Wire-Mesh Products, Inc.

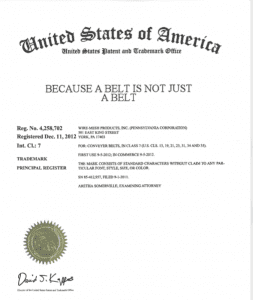

“Because A Belt Is Not Just a BeltTM”

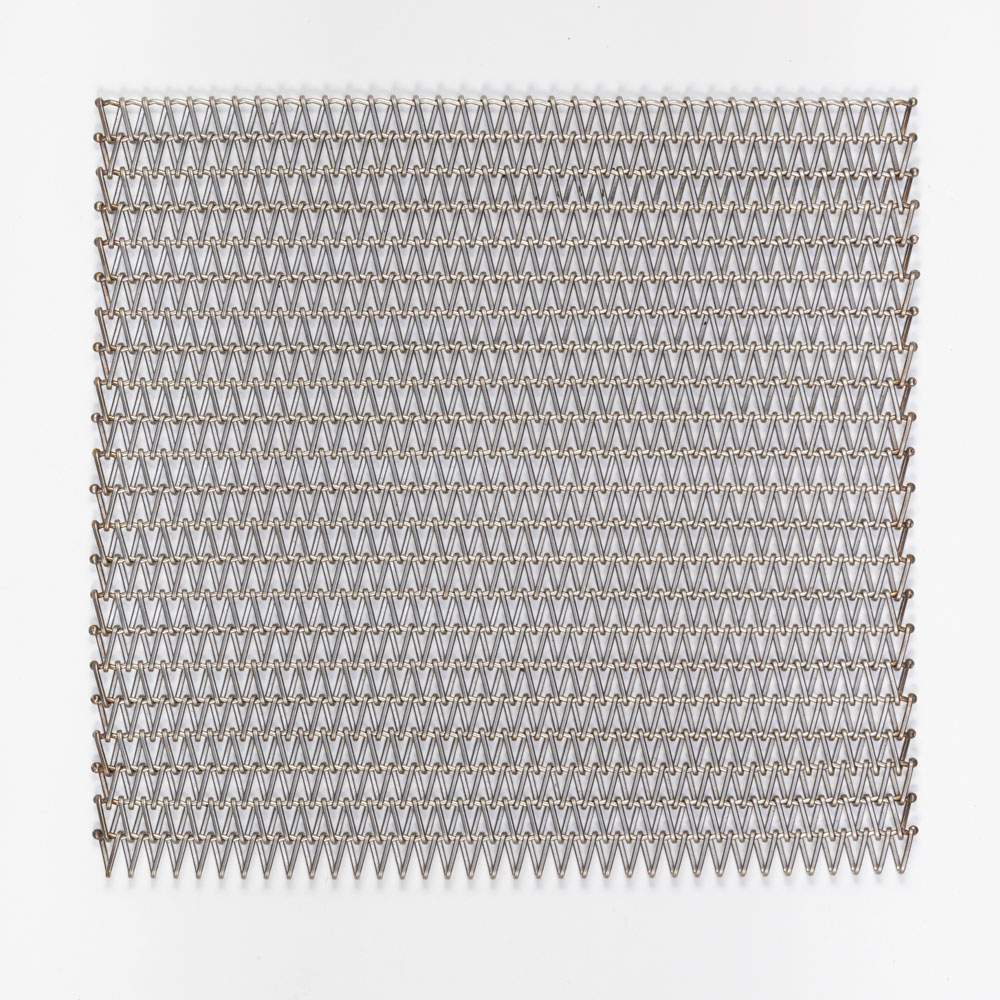

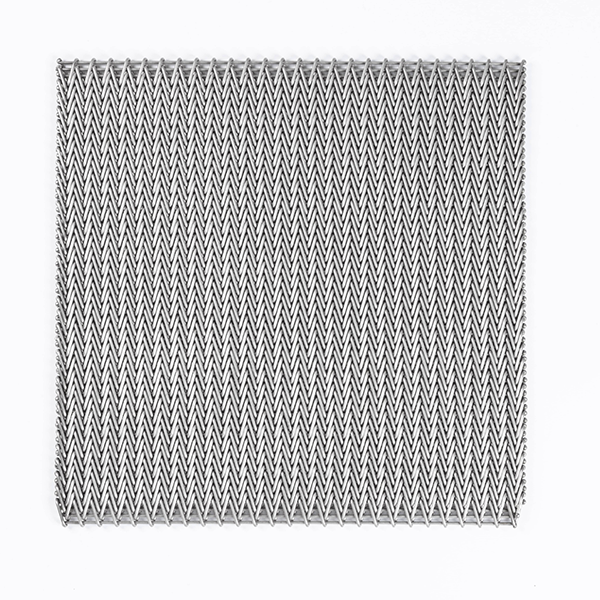

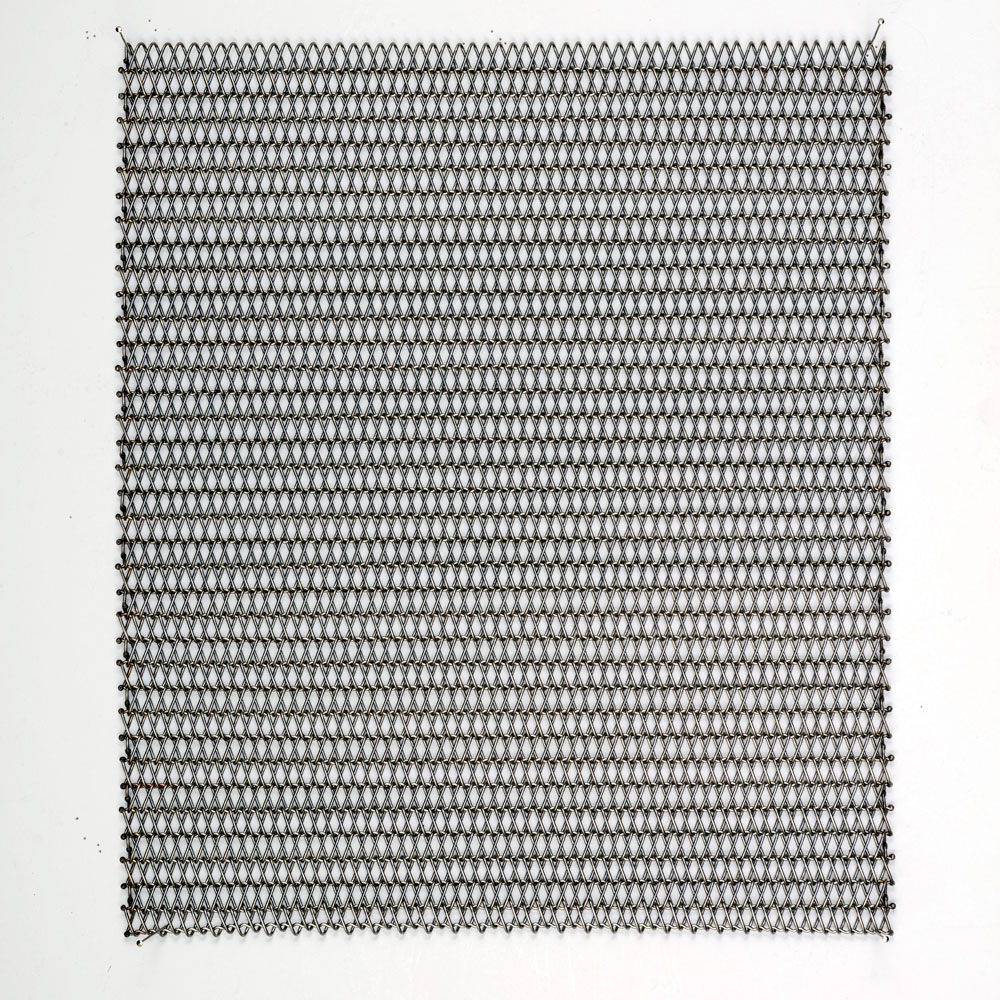

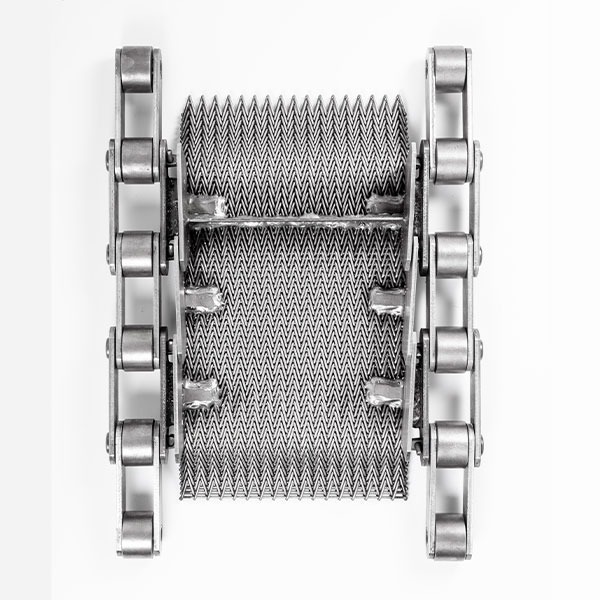

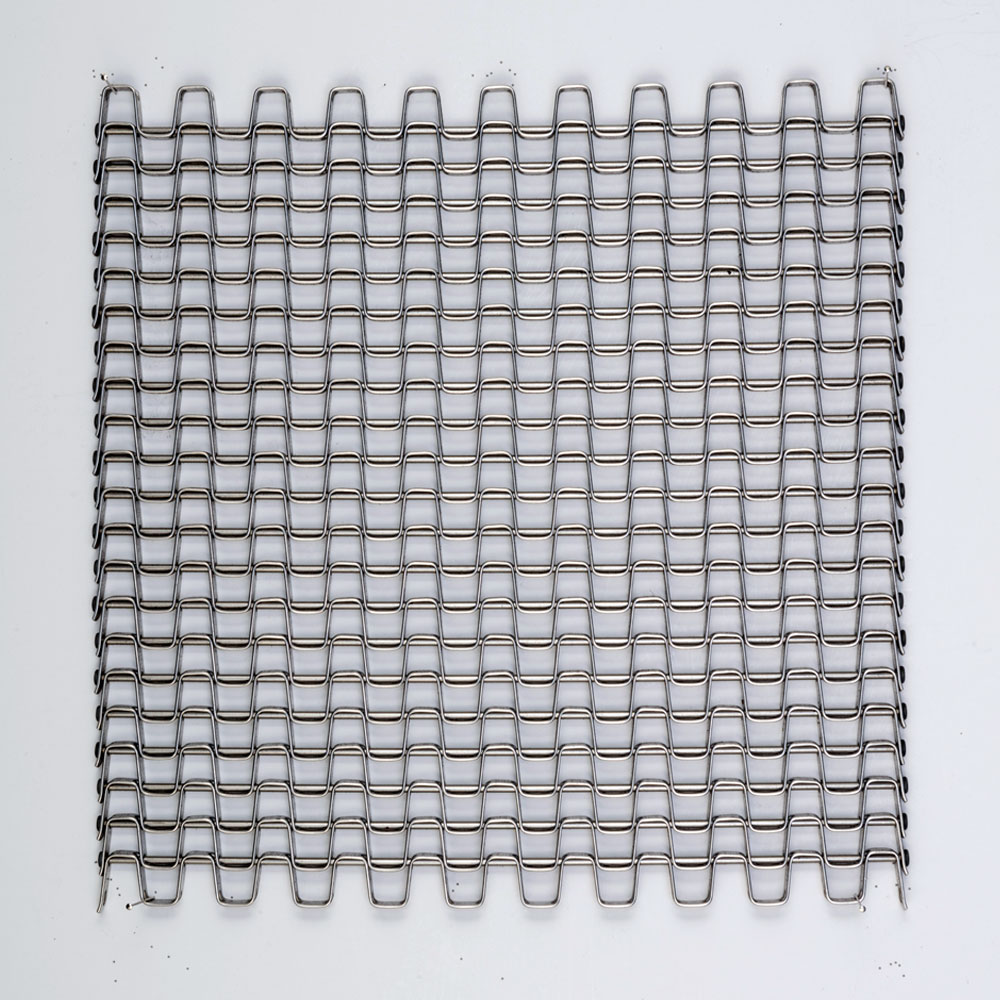

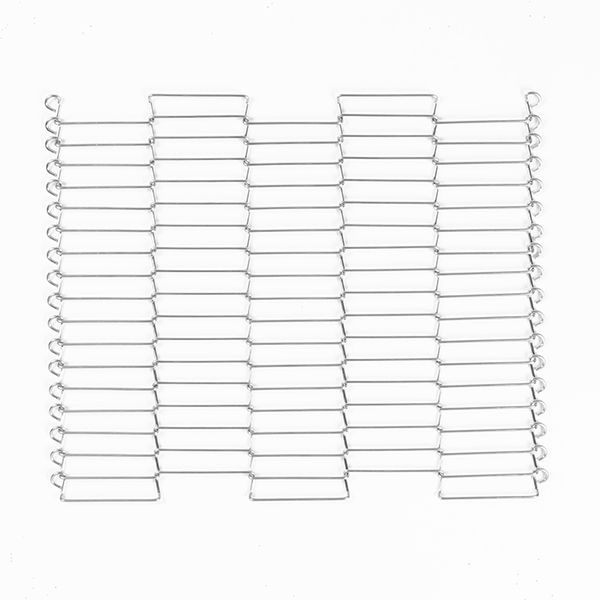

Whether your belting needs are at low or elevated temperatures, low or high corrosive environments, our experience, engineering and manufacturing capabilities can meet and go beyond any wire mesh belting requirement you have. We look forward to the opportunity to exceed your expectations with our custom engineered solutions.

“Because A Belt Is Not Just a Belt TM”

There are many factors to why a belt succeeds or fails. At Wire-Mesh Products, Inc. we engineer and operate with the understanding that a belt is not just a belt and that each customer’s belting application is unique. We don’t sell belts off the shelf. Never have. We custom make each belt only after determining all the factors that contribute to it’s ultimate success or failure. Solving complex belt issues is our ‘thing’ and our belts often out-perform our competition due to the upfront time spent understanding the environment in which the belt is operating.

You Know Your Industry. We Know Your Perfect Belt.

Since 1975, Wire-Mesh Products has been committed to producing the highest quality custom wire mesh belts in the business across all industries. From basic carbon steel belts to high metal alloy compositions to china to food processing equipment, we’ve supplied over 1,000 customers in more than 100 industries worldwide. We’ve gained the trust of companies and industries all over the world through our hard work, dedication, and unparalleled services..

We Are Hiring!

Our growing company has many avenues for advancement and long-term employment for a career in manufacturing.

Learn How We Can Help With A Belt That Lasts