How to Measure / Conveyor Belt Material Chart

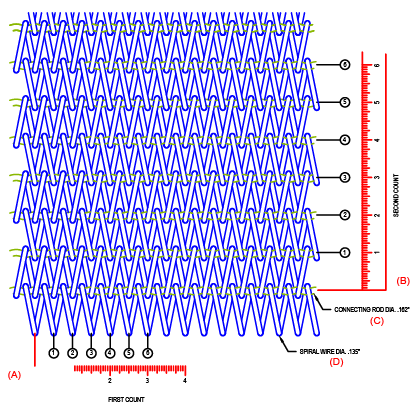

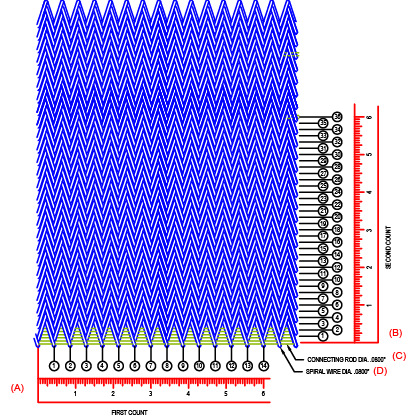

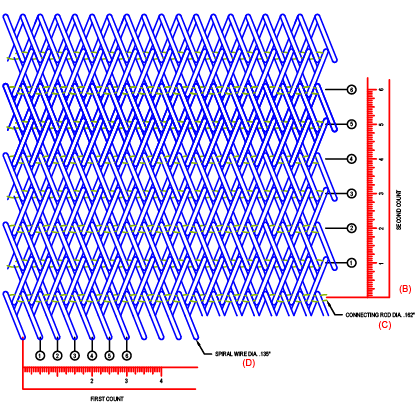

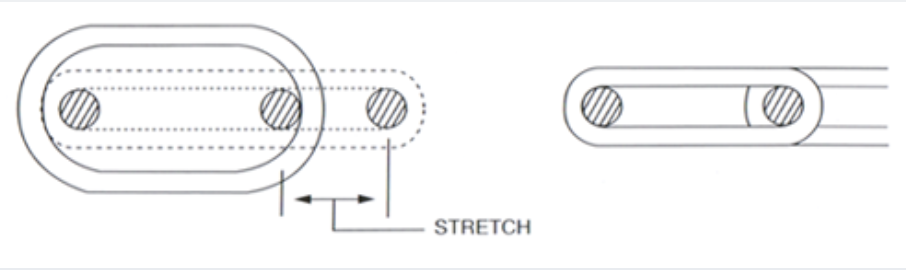

How to Measure Your Belts

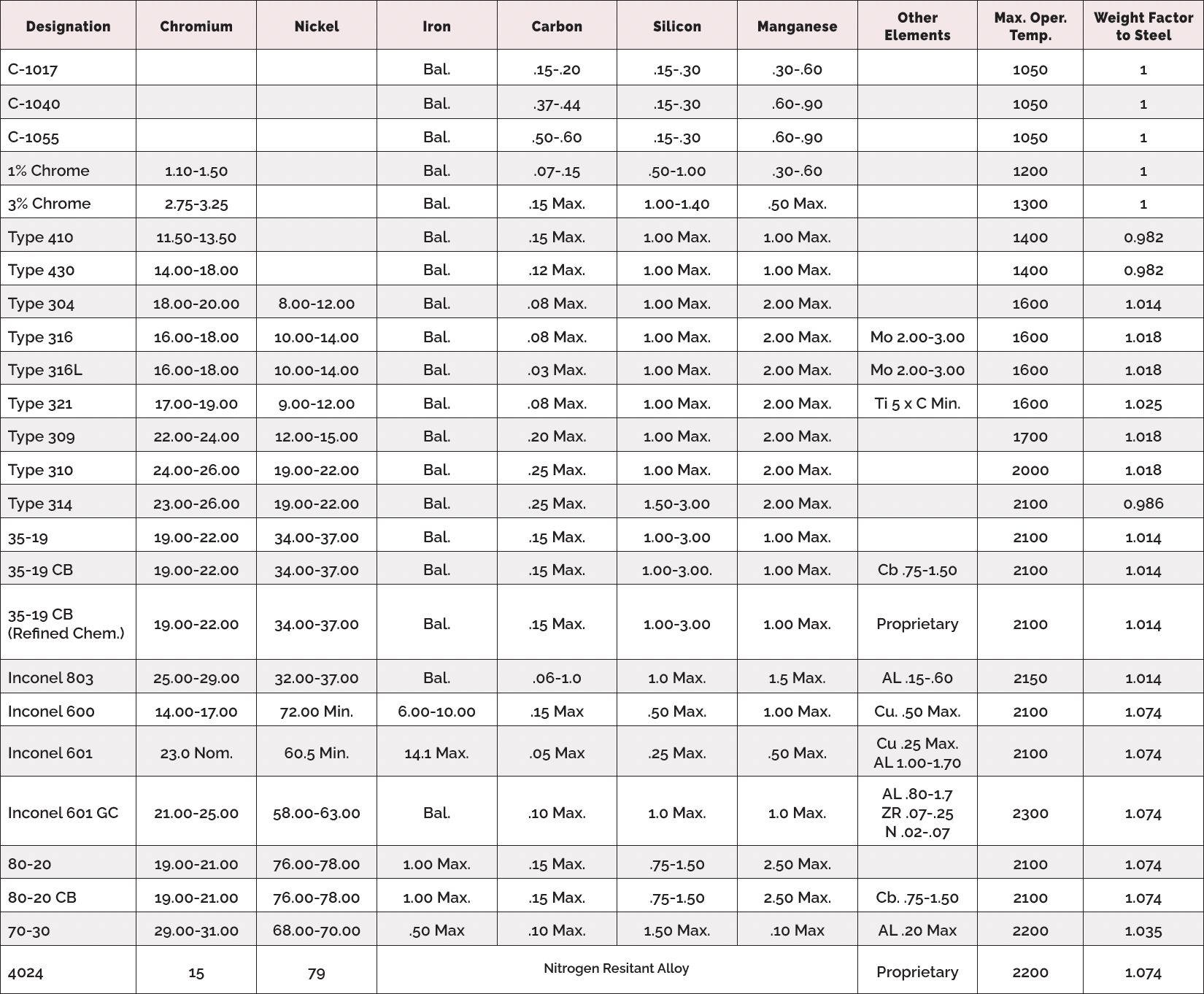

Conveyor Belt Material Chart

As a result of our experience, Wire-Mesh Products has developed benchmarks for proper alloy selection. From start to finish, we make sure to only provide the highest quality materials to our customers and their operations. We work with our trusted suppliers in a continuing effort to develop new conveyor belt materials and refine the chemical composition of existing alloys.

Our material is 80% recyclable for LEEDS building materials and/or corporate recycling objectives. View real time data and pricing on nickel in today’s marketplace: Stainless Steel News & Nickel Prices