05 Sep Picking The Best Conveyor Belt: Why Use Balanced Weave Conveyor Belts?

Deciding what the best conveyor belt is for your business depends on a number of factors. However, there are some belts that have become the predominant choice across virtually every industry.

In this blog, we will discuss variations of balanced weaves as well as how using balanced weave conveyor belts can benefit your business operations in the long run.

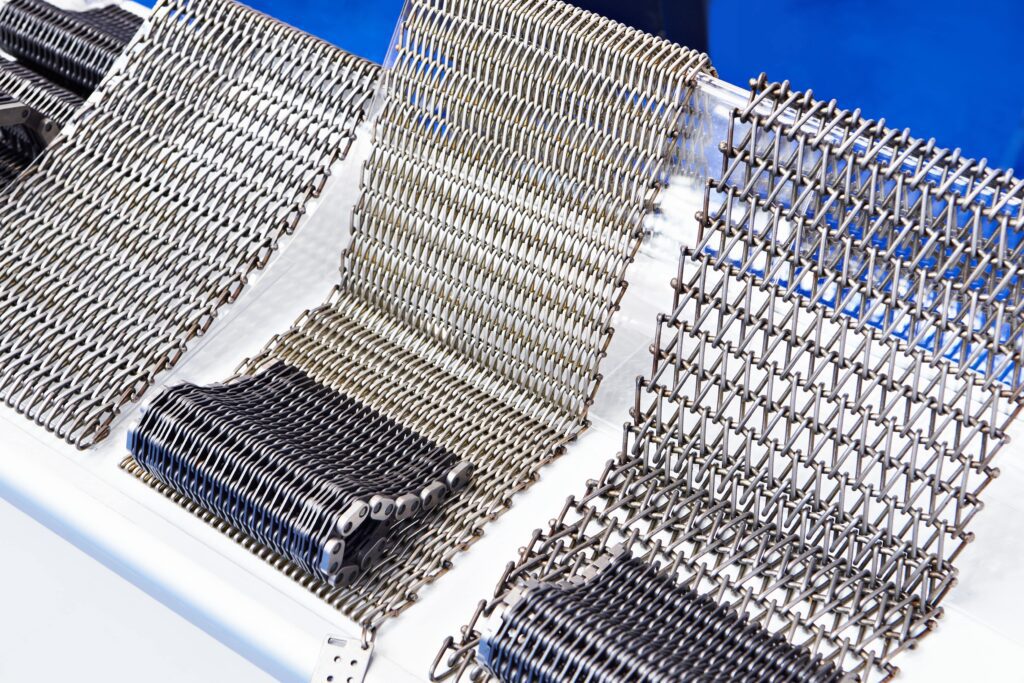

What Is A Balanced Weave?

A balanced weave is a series of alternating single or double left and right-handed spirals connected by a straight or crimp rod.

This versatile design is what makes balanced weaves the predominant choice in a wide range of conveyor belt systems and industries from packaging and handling to food processing.

Both positively driven balanced weave designs, like pin roll or cleat-driven belts, and chain-driven belts, use crimped rods. However, sometimes there isn’t enough room to put a notch or crimp in the rod. When this is the case, a straight rod will need to be inserted instead.

Types Of Balanced Weave Mesh Belts

Wire-Mesh Products offers different types of balanced weave belts making it easy for businesses to find the type best suited for their operations.

Our team flattens round wire to provide a wider, smoother surface paired with a crimp connector specifically designed to match the flattened spiral. This helps with belt tracking as well as product stability.

Sprocket & Pin Roll Driven Balanced Weave Mesh Belt

Ideal for lightweight applications in temperatures under 190℉, sprocket and pin roll-driven belts provide businesses with the advantage of having a smaller diameter sprocket with teeth. This design prevents slipping and helps belt tracking.

3 Balanced Weave Variations

There are multiple balanced weave variations and accommodations businesses can use if they choose to invest in this type of belt.

For example, balanced weave belts can be woven to accommodate larger rod or pipe diameters if necessary. This means they can have uniform or uneven heights, depending on what a business needs.

If a belt is uneven, it may result in a “speed bump”, however, this can actually be helpful in certain situations.

Each variation has its own advantages, and the choice of which one to use will depend on what type of operations a business is running as well as personal preference.

The most important thing to remember when choosing which belt is right for you is to talk to an expert who will be able to analyze your needs and advise you on the best type of variation and weave. Below, we’ll go into further detail about the common balanced weave variations.

1. Regular Spiral Profile

Just as the name suggests, a regular spiral profile features a consistent pattern of woven wires. These spirals are considered to be more “egg-shaped” rather than those that are flattened.

2. Low Spiral Profile

Low spiral profile, or “pre-flattened” belts are woven like a race track. This design is important for belts that are exposed to high temperatures and processes where stretching is a large issue.

Other belts, like those that are more egg-shaped, are prone to stretching more quickly, causing issues in production and reducing belt life. A low spiral profile’s goal is to increase the longevity of the belt without stretching too much.

At Wire-Mesh Products, we also specialize in high-temperature conveyor belts. This allows us to provide our customers with belts that not only track straighter, permitting a longer belt life.

3. Flattened Spiral Top Surface

Unlike the prior variation, a flattened spiral top surface weave can be detrimental if it is used in environments with high temperatures.

The food industry is one of the only industries that use this type of belt, and only food conveyor belts that are exposed to mild conditions will be able to do so.

In addition, contrary to what the name may suggest, flattened spiral top surface weaves do not mimic a tabletop surface. Due to its design, the weave will have a minor pitch in one direction or the other. This means that whatever products are being transported may be at risk of toppling or spilling over.

Edgewear Options & Solutions

Balanced weave conveyor belts typically use a standard weld edge design. At Wire-Mesh Products, we offer the heli arc welded edge for balanced weaves.

We also provide businesses the opportunity to upgrade to our special truss edge, which is what we use on our ToughSert belts.

Choosing to upgrade your edge design depends on your belt as well as your personal preference. For example, one of our clients in the tortilla industry can use the heli arc welded edge, but they prefer to have a truss edge on their balanced weave belts.

However, it’s important to note that not every balanced weave conveyor belt can use a special truss edge. Our team of experts will be able to help you decide on the best edge option for your business.

In addition, if your business continues to have edgewear issues, we have the knowledge and ability to find the proper solution.

Benefits Of Using Balanced Weave Conveyor Belts

From their versatility to their effectiveness, there are many reasons people find balanced weaves to be the best conveyor belt option. Continue reading to learn more about what makes them superior.

Performance

Balanced weave belts are known to perform better than rod-reinforced belts. Because rod-reinforced belts are antiquated, or old-fashioned, they are harder to splice and usually have more tracking issues.

On the other hand, balanced weave belts are easier to make, have fewer tracking issues, and have an overall longer belt life.

When compared to double-balanced weave belts, balanced weaves perform just as well. While double-balanced belts have a slightly stronger edge and provide more airflow, they need to be weaved thicker. This makes them more prone to stretching, whereas balanced weaves are not.

Overall, after years of experience, we’ve found that 8 out of 10 times, customers will choose balanced weave belts over others.

Sorry, the comment form is closed at this time.