22 Aug Conveyor Belt Components: Discover The Benefits Of Custom Conveyor Belt Parts

Oftentimes, companies focus on conveyor machinery as a whole. The belts, themselves, are what keep production moving swiftly and smoothly.

However, understanding the conveyor belt components and parts that support the belt is crucial for any company to run a successful business.

At Wire-Mesh Products, we understand that each belt is unique, and therefore so are its parts. Continue reading this blog to learn more about conveyor belt components and how investing in custom belt parts and solutions can benefit your company.

Conveyor Belt Design

Every conveyor belt is designed for a specific purpose or industry. For example, while they may seem similar at first glance, a conveyor belt designed for food processing industries will include characteristics that a high-temperature industrial belt may not need.

When it comes to conveyor belt components and parts, the possibilities range widely, but understanding what their belt needs to function efficiently can make or break a company’s entire production process.

Generally speaking, there are 3 elements that companies should consider when assessing the capabilities of their belts: weave and strength, material, and splicing.

Belt Weave and Strength

Conveyor belt weaves refer to the specific arrangement of interwoven wires that make up the belt’s structure. There are many kinds of weaves all providing different functions:

In addition to industry requirements, the ideal weave and strength of a conveyor belt will depend heavily on a variety of factors:

- Maximum weight of materials being transported.

- Type and size of materials being transported.

- Processing temperature, atmosphere, and other processing parameters.

Wire-Mesh Products also provides customers with enhancements for their weaves, such as our patented ToughSert addition which can be added to compatible Wire-Mesh belts to improve their performance. This enhancement will ensure belts have less stretch and less camber, and even delay belt splitting.

Belt Material

Similar to the weave type, the conveyor belt material will depend on industry, process conditions, and the transported product.

Wire-Mesh Products has worked to develop benchmarks for proper alloy selection, ensuring companies are given the highest quality and long-lasting materials:

- High Carbon Steel

- Galvanized

- 430ss

- 304ss

- 316ss

- 314ss

- 35-19cb

- Ni V

- Inconel® Alloys (600, 601, etc.)

- Others

Some companies already know what materials they prefer to work with or they have an existing belt that is in need of matching conveyor belt parts. Wire-Mesh can provide belt parts like chains, splicing rods, and sprockets in their respective material.

If a component wears or becomes old, it will affect overall belt performance. When this happens, Wire-Mesh Products can supply or recommend the proper sprocket that drives the belt.

Splicing

While splicing isn’t something that would be included on a list of conveyor belt components, it’s a process that plays a huge role in every industry.

Conveyor belt splicing is the process of joining two ends of a belt to create a continuous loop. This occurs during the initial manufacturing of a belt, but can also be implemented to repair a damaged belt or if a belt needs to be adjusted in length.

The correct technique will depend on the belt itself. Companies that need assistance with belt splicing can call Wire-Mesh Products to discuss.

Finally, we can send splicing rods or extra mesh to a company that needs to lengthen or shorten an existing belt.

Custom Conveyor Belt Parts

Custom Conveyor Belt Parts

As we mentioned before, conveyor belt parts can vary immensely depending on what the belt is being used for specifically.

We know that every belt is at risk of being damaged. However, sometimes the entire belt doesn’t need to be removed, it simply needs supporting parts to improve its performance.

For example, if the edge of your belt falls off, we can send you a spare retaining edge to keep any products from rolling or slipping onto the ground during production. Some other common conveyor belt components that can be provided include:

- Flexplates

- Flights

- Chain components

- Cotter pins or washers

- Spare mesh

Since Wire-Mesh Products has experience manufacturing custom conveyor belt designs, from belt edges to chain conveyor belt parts, we’re prepared to ensure all your needs are met if something goes wrong with a belt you already have.

Custom Conveyor Belt Components Based on Drive

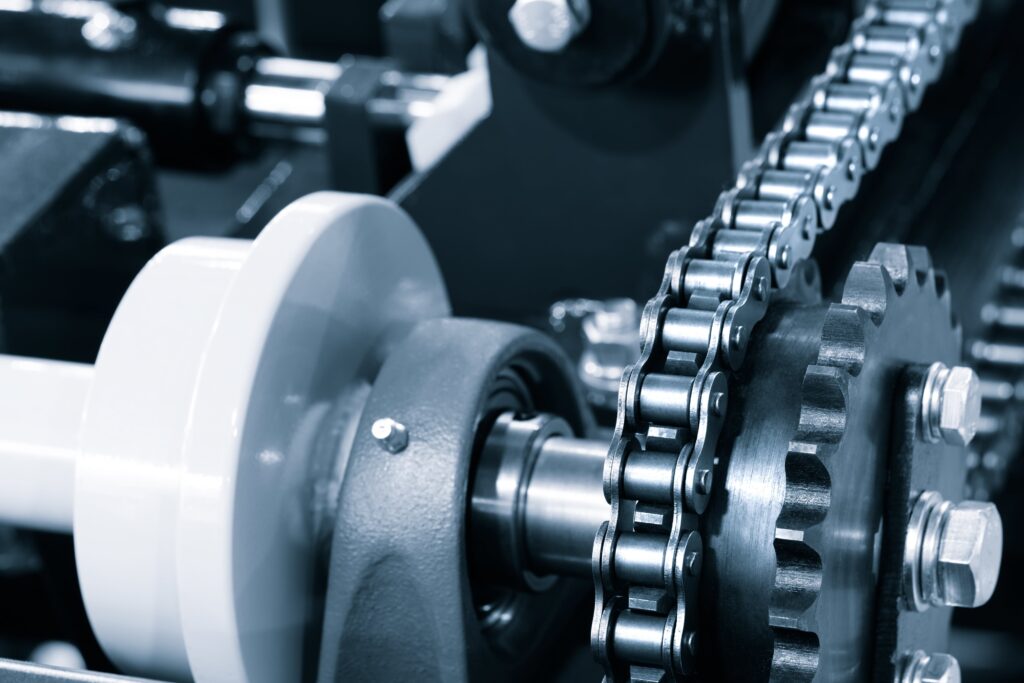

There are two main ways to drive belts: friction and positively driven.

Friction-driven belts include a plain or rubber-lagged drum that spins, initiating the belt’s movement. Positively-driven belts can come in many variations, but the general idea is that something engages the belt, pushing it into movement. For example, a bicycle chain with sprockets.

However, conveyor belt components will differ depending on variations of positive drive belts. While they both have teeth that drive the belt, pin roll or cleat track sprockets are different from chain sprockets.

Pin-roll or cleat track sprockets engage the mesh opening itself, whereas the chain sprockets will engage the chain.

Chain Conveyor Belt Parts

- Shafting and Sprocket

- Roller Chain

- Cast Pintle Chain

- Roller Chain Sprockets

Spiral Woven Conveyor Belt Parts

- Shafting and Sprocket

- PB Sprockets

- CTB Sprockets

- PB and CTB Sprockets

Wire-Mesh Products can provide companies with chain sprockets and positively driven mesh sprockets.

Custom Conveyor Belt Parts

Custom Conveyor Belt Parts

Sorry, the comment form is closed at this time.