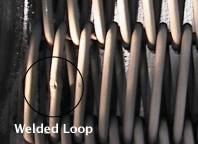

When a new high-temperature furnace began experiencing rapid stretching and unusual distortion of its conveyor belt, the client turned to Wire Mesh Products for a solution. What they found was not a minor flaw, but a series of fundamental manufacturing defects in the original belt’s construction.

This case study details how Wire Mesh Products diagnosed the problem and delivered a superior, precision-engineered belt that restored operational efficiency and provided long-term reliability.