A Midwest manufacturing company turned to Wire-Mesh Products after struggling with excessive conveyor belt expenses that were nearing $200,000 annually. With maintenance teams frustrated by repeated belt failures and leadership demanding answers, the company needed a trusted partner to identify the root cause of the issue and deliver a lasting, cost-effective solution.

From $200,000 to $36,000: Facing Escalating Conveyor Costs Head-On

Pinpointing the Cause of Chronic Belt Breakdowns

The customer had been advised by a competing belt supplier that their equipment was to blame for the frequent belt replacements and high costs. Despite repeated adjustments and maintenance efforts, the problem persisted. Belt failures continued at a rapid pace, resulting in operational inefficiencies and depleting the maintenance budget.

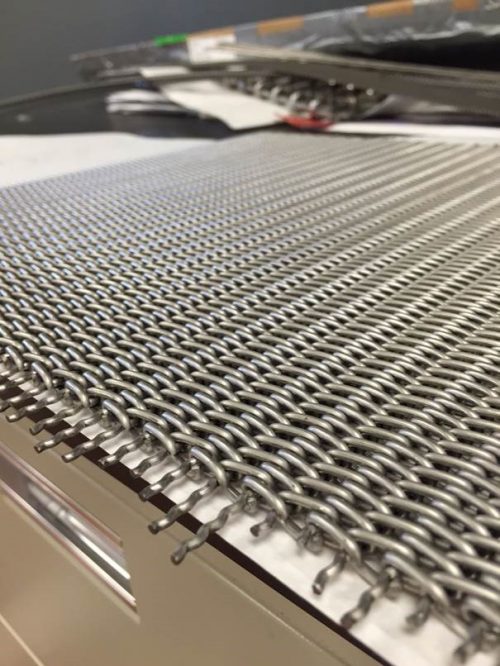

Reengineering Performance at the Belt Level

After conducting a thorough review of the customer’s equipment and the competitor-supplied belts, Wire-Mesh Products revealed that the equipment was functioning properly and did not require modification. Instead, the real issue was poor belt construction combined with an inflated belt price.

Wire-Mesh Products supplied a redesigned belt engineered for durability and performance. The first and second sets of Wire-Mesh belts each ran for six months, already doubling performance compared to the previous belts and immediately reducing costs.

Delivering Long-Term Reliability and ROI

The cost savings were immediate and substantial. Annual belt expenses dropped from nearly $200,000 to approximately $36,000, delivering an annual savings of $164,000. Even more impressive, the current set of Wire-Mesh belts has been running for 12 months and counting, at an annual expense of just $18,000, which is nearly 90% less than the original deficient belt solution.

The result is a more reliable operation, a satisfied maintenance team, and a long-term cost reduction that exceeded the customer’s expectations.

Ready to put an end to costly belt failures? Contact our specialists today for a comprehensive belt analysis.