A Midwest company contacted Wire-Mesh Products looking for help to reduce their annual belt costs of nearly $200,000. Maintenance was frustrated, and management was pushing for answers. They needed to find the cause and stop the money hemorrhage.

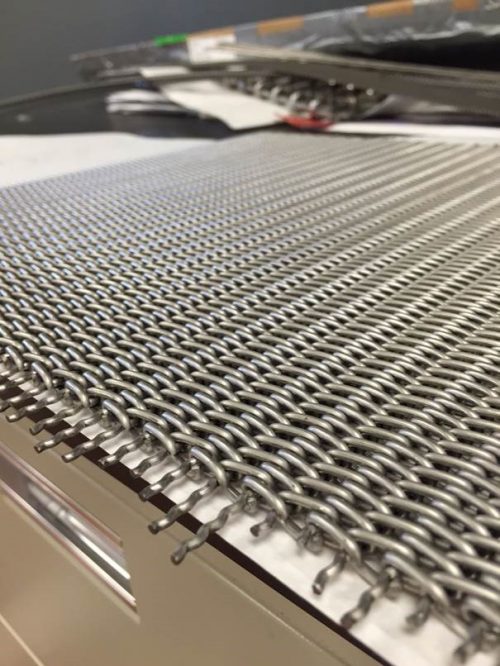

After careful review of their equipment and the belts being supplied by a competitor, Wire-Mesh concluded that the only item that needed to be corrected was the belt itself. There was nothing wrong with the equipment, as the belt supplier was claiming: only inferior belt construction.

The first set of belts Wire-Mesh supplied ran for six months as did the second set, so costs immediately dropped with a savings of $164,000 annually. The newest (and current) set has been running for 12 months – something even the client was thrilled to discover when we spoke to them this week – at an annual expense of $18,000. That’s almost 10% of the cost of the original deficient belt.

The difference is quality and commitment to doing things right. Since 1975, Wire-Mesh Products has been committed to producing the highest quality custom wire mesh belts in the business. From basic carbon steel belts to high metal alloy compositions to china to food processing equipment, we’ve supplied over 500 customers in more than 100 industries worldwide. And we’re ready to serve you because quality speaks for itself. Contact Wire-Mesh to see how we can help your business today.