When it comes to conveyor belt materials, the options are virtually endless, and navigating them can be difficult. Continue reading to see how our experience with select alloys and materials can help you find the ideal conveyor belt material for your specific application.

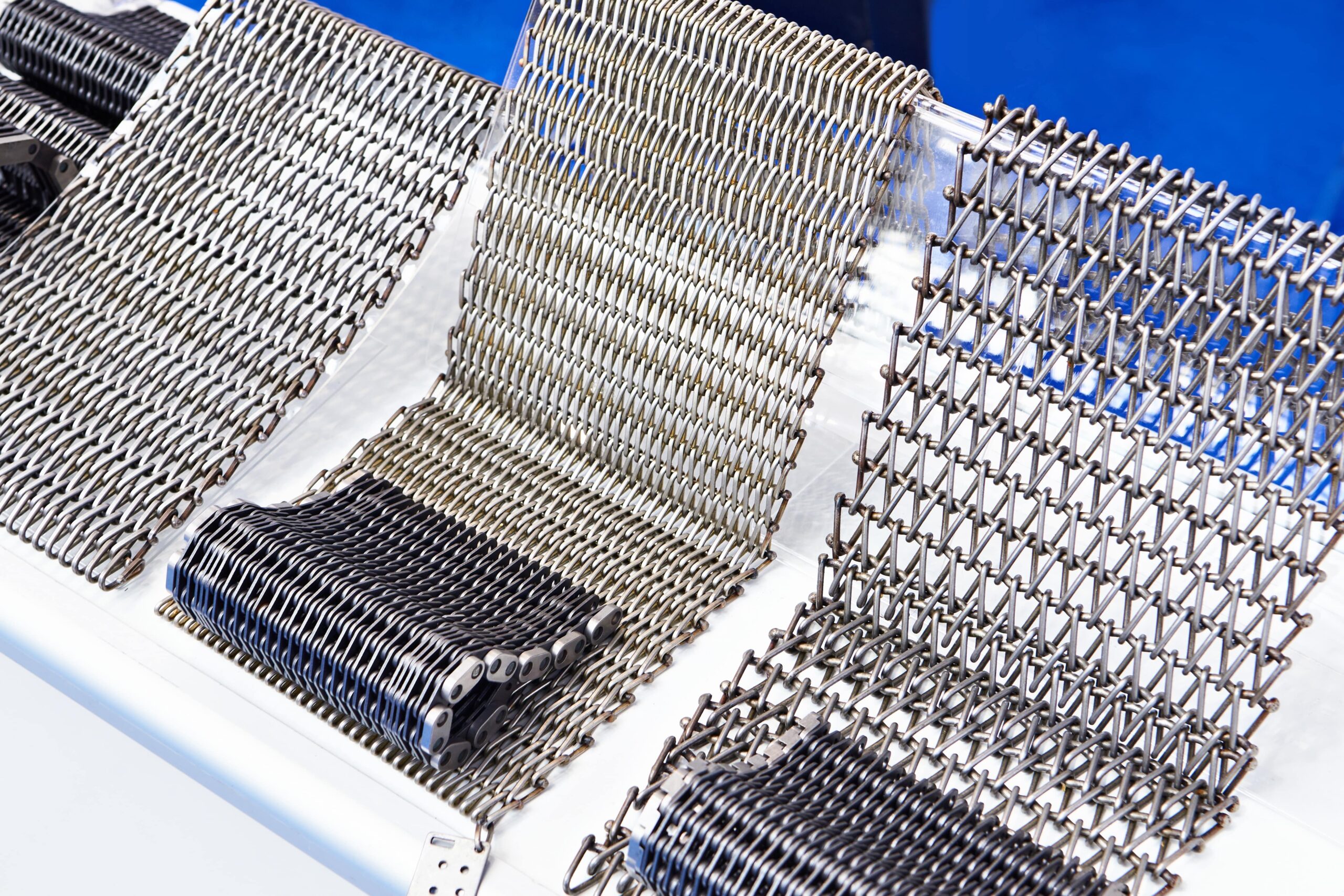

Benefits Of Using Wire Mesh As A Conveyor Belt Material

Because of their unique design and material makeup, wire mesh belts offer advantages for several industries from high-temperature industrial to food packaging and handling. Some of these benefits include, but are not limited to:

- Airflow and drainage. The surface openings in wire mesh belts allow for improved air circulation and fluid drainage, something solid plastic and rubber belts are unable to offer.

- Durability and handling. Wire mesh conveyor belts are engineered to withstand heavy loads.

- Versatility. Depending on your needs, some wire mesh belts and their components can be customized to meet the specific requirements of an industry or business.

- Temperature resistance. Able to withstand extreme temperatures, both high and low, wire mesh belts work for a variety of applications and environments.

- Cleanliness. Designed to be easy to clean and maintain, wire mesh belts can help you minimize downtime, keep productivity high, and with the right care can last longer than other belts.

Wire mesh belts can be made with a variety of materials from carbon steels to chromium-nickel stainless steels. Below, we’ll dive deeper into select alloys and materials we use to design our wire mesh belts.

Conveyor Belt Material Selection

As we mentioned above, wire mesh belts offer many benefits, but to reap these benefits, you have to choose the material best suited for your environment. Understanding specific conveyor belt material properties will help you decide which material can and cannot withstand the requirements of your industry.

It’s important to note that when it comes to conveyor belt material and alloy selection, having guidance from experienced professionals can go a long way in ensuring you don’t run into belt problems in the future.

If you have any questions or concerns, talk to one of our material specialists to ensure you get a belt that can meet your unique needs.

We’ve broken down the most common conveyor belt materials used in low to high temperatures environments.

Low Temperatures

The following are select alloys and materials to consider for processes 600 ℉ and under.

Carbon Steel

With varying carbon contents, Carbon steel alloys provide good strength and abrasion resistance at temperatures up to 600 ℉. While steel can withstand higher temperatures in some applications, it is generally not recommended to exceed approximately 600 ℉ as the strength of carbon steel dramatically falls above this temperature.

Carbon steel is commonly used in food processing, heat treatment, and general conveyors. However, since it will oxidize, this alloy should not be used where rust would pose a problem.

430 Stainless Steel

The next conveyor belt material for low temperatures is 430 stainless. As its name suggests, this material has stainless steel properties due to its chromium content, and since it is a magnetic alloy, it can be used with a magnetic drive to aid in belt tracking.

430 magnetic stainless is popular in the food industry. It falls in the ferritic stainless category where elevated temperatures aren’t a factor. For budget-conscious customers, this alloy provides good rust and corrosive resistance.

Galvanized Steel

Galvanized steel wire comes either electro-plated or hot-dipped with zinc. Unless otherwise specified, we recommend electro-plated galvanized steel because it offers better quality and a long-lasting coating.

Medium Temperatures

Ranging from 600 ℉ to 1250 ℉, medium-temperature conveyor belt materials commonly include these types of stainless steel.

304 Stainless Steel

This austenitic steel is commonly used in the food industry and high-temperature environments up to 1250 ℉. It has good oxidation resistance with a chemical composition of approximately 18% chromium and 8% nickel.

316 and 316Ti Stainless Steel

Since this material includes molybdenum, 316 stainless steel provides increased resistance to corrosion from soaps, detergents, and salt. It can generally withstand temperatures up to 1250 ℉ making it a common selection in the aluminum brazing processes for condensers and cooling radiators.

At Wire-Mesh Products, we also offer 316 titanium which is a version of the 316 that has even higher protection against corrosion and improved strength.

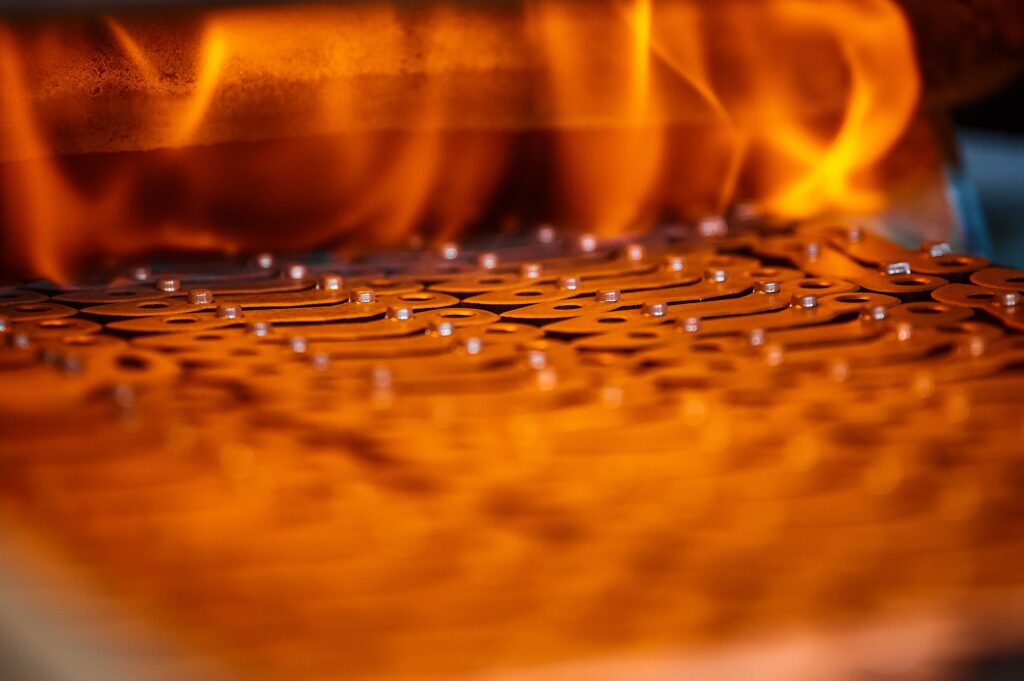

High Temperatures

Your conveyor belt material and alloy selection for high-temperature environments will vary more than those in the low or medium categories. These belts can withstand temperatures ranging from 1250 ℉ and higher.

314 Stainless Steel

314 stainless steel performs very well in temperatures ranging from 1700 ℉ to 2300 ℉. This material is a very cost-effective solution in this temperature range. It offers excellent heat and oxidation resistance which is why it’s popular in the powder metal industry.

3519 CB (NB)

Known as the best alloy for fluctuating temperatures, 3519 CB (NB) can be used in temperatures from 1250 ℉ to 1750 ℉. It handles both carbide precipitation and carburization well, making it ideal for the heat treat industry.

Inconel 600 and 601

If you need to select alloys for environments at 1800 ℉ or higher, Inconel 600 and 601 are good materials to consider. Inco 601 works very well in high-temperature oxidizing environments while Inco 600 works well in high-temperature carburizing atmospheres.

Inconel 601 GC

This material is the grain-controlled version of Inconel 601. Inconel 601 GC is best used for extreme temperatures of about 2100 ℉ or higher and is an ideal choice for industries where cleanliness is important such as technology processing.

We have experience working with Inconel 600 and 601. For more information regarding these materials, give us a call to discuss your options today.

80-20 CB / NIVCB

The last conveyor belt material for high-temperature environments is 80-20 CB / NIVCB This alloy is typically used in the electronic and high-tech industries. 80-20 CB / NIVCB / is a very clean alloy, which essentially means it has almost no iron in it.

At Wire-Mesh, we can create a “zebra belt,” which is a combination of several alloys, to test what works best for your application. Then based on the results we find, we can mix alloys to meet your unique requirements.

Need help finding the right conveyor belt material for your operation? Talk to one of our specialists to see what we can do for you.